Zenera in Industrial Manufacturing

Compressing 40-Month Design Cycles to 10 Months: The Agentic AI Approach

Executive Summary

Industrial manufacturing operates under constraints that break conventional AI approaches: 80 years of legacy archives in heterogeneous formats, engineering drawings and blueprints requiring visual reasoning, real-time CAD and simulation tool integration, multi-system dependency tracking, and executive decision support requiring defensible ROI projections.

A valve business unit targeting 75% reduction in design cycle time—from 40 months to 10 months—represents the industrial equivalent of breaking the sound barrier. This is not a chatbot problem. It requires engineering AI infrastructure that can reason across decades of institutional knowledge—including visual artifacts like blueprints, P&IDs, and CAD drawings—synthesize with modern engineering tools, and surface actionable intelligence at every level of the organization.

The core insight: Zenera is not a text chatbot—it is an engineering AI platform with native visual recognition, diagram reasoning, and CAD generation capabilities. These use cases demand capabilities that LangChain, RAG pipelines, and fine-tuned models cannot provide—visual reasoning over engineering drawings, transactional operations across legacy archives and live CAD systems, self-coding integrations with proprietary simulation tools, and reasoning graphs that trace requirements through verification. Only Zenera’s agentic architecture delivers this level of industrial intelligence.

Engineering AI: Beyond Text Chatbots

Manufacturing intelligence lives in visual artifacts: engineering drawings, P&ID diagrams, assembly blueprints, weld symbols, GD&T annotations, flow schematics, and CAD models. Text-based AI systems are fundamentally blind to this domain.

| Capability | Description |

|---|---|

| Blueprint & Drawing Recognition | Extract dimensions, tolerances, material callouts, and revision history from scanned engineering drawings |

| P&ID Diagram Understanding | Parse piping and instrumentation diagrams, identify valve types, flow paths, and control logic |

| CAD Model Reasoning | Analyze 3D geometry for interference, stress concentration, and manufacturability |

| Visual Failure Analysis | Correlate failure photographs with design features across historical archives |

| Diagram Generation | Output engineering schematics, assembly drawings, and annotated CAD views—not just text |

| GD&T Interpretation | Reason over geometric dimensioning and tolerancing symbols to validate design intent |

| Cross-Modal Correlation | Link text specifications to visual representations and vice versa |

"Engineers don’t work in text. They work in drawings, models, and diagrams. Zenera reasons natively in this visual engineering domain."

Why LLM + Open-Source Libraries Fail in Industrial Manufacturing

| Industrial Requirement | LangChain + RAG Reality | Zenera Capability |

|---|---|---|

| Engineering drawing recognition | Text-only; blind to blueprints and diagrams | Native vision models parse drawings, P&IDs, and schematics |

| CAD geometry reasoning | Cannot process 3D models | Analyzes STEP/IGES geometry for stress, interference, and manufacturability |

| Visual failure correlation | Cannot link failure photos to designs | Cross-modal reasoning connects images to CAD features |

| 80-year legacy archive ingestion | Context overflow; cannot reason across 10,000+ documents | Hierarchical multimodal indexing with provenance tracking |

| CAD/PDM system integration | No SolidWorks or Teamcenter connectors; manual export required | Self-coding agents synthesize API integrations at runtime |

| Diagram and schematic generation | Text output only | Generates annotated drawings, flow diagrams, and CAD views |

| Simulation code generation | Generic code that ignores domain physics or constraints | Domain-grounded code synthesis validated against historical results |

| Cross-system dependency tracking | Separate queries per system with no transactional joins | Atomic operations across AgilePlace, ERP, and engineering archives |

| Requirement-to-test traceability | Text matching only; no formal reasoning graphs | Semantic mapping with auditable compliance chains |

| Executive ROI modeling | Static calculations; no scenario analysis | Dynamic decomposition with Monte Carlo confidence intervals |

| PBAC security enforcement | Application-level only | Integrated Azure Entra ID with corpus-level access control |

Use Cases

Choose a persona to jump into its dedicated deep-dive page with the full scenario breakdown.

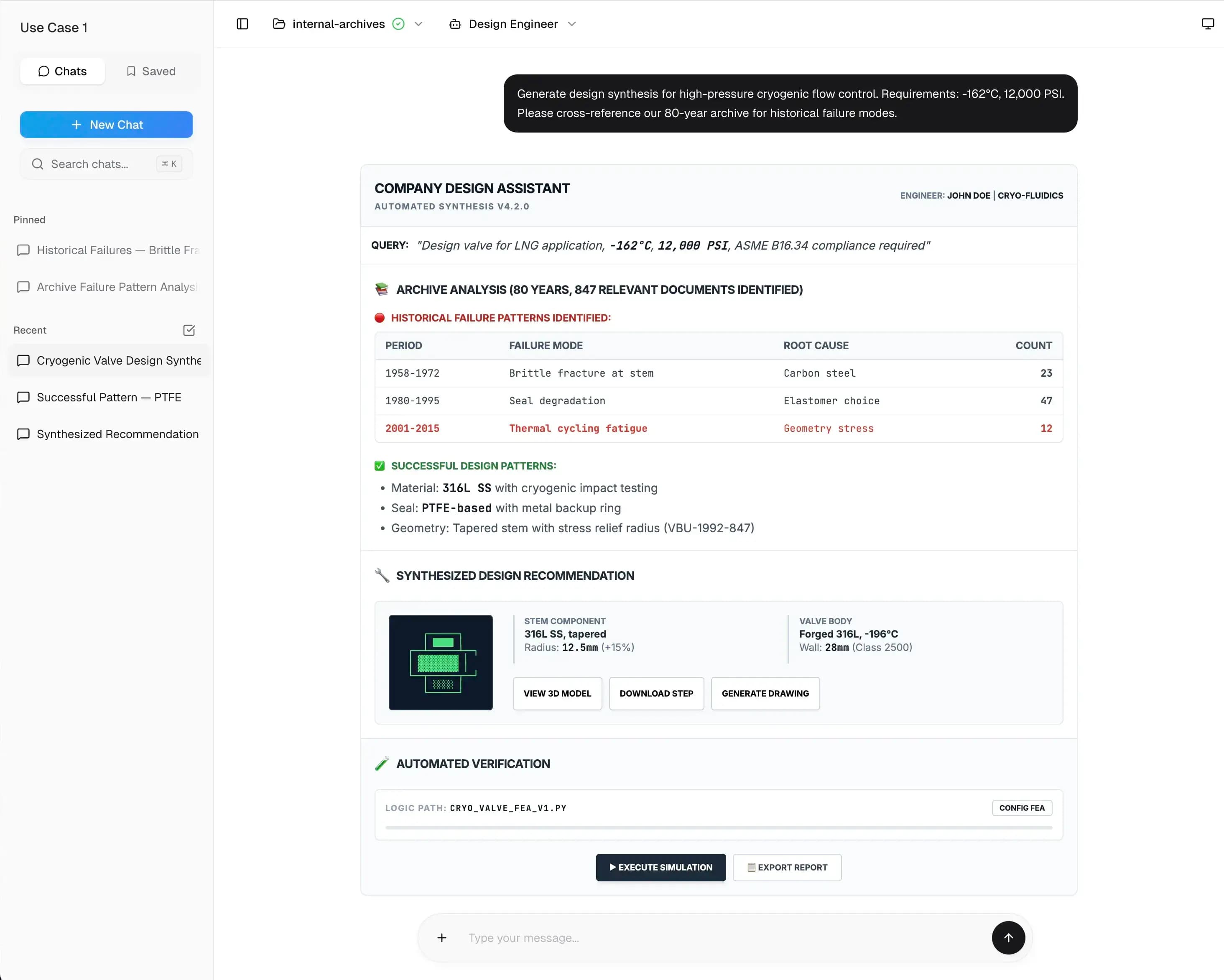

Automated Legacy-Informed Design Synthesis & Verification

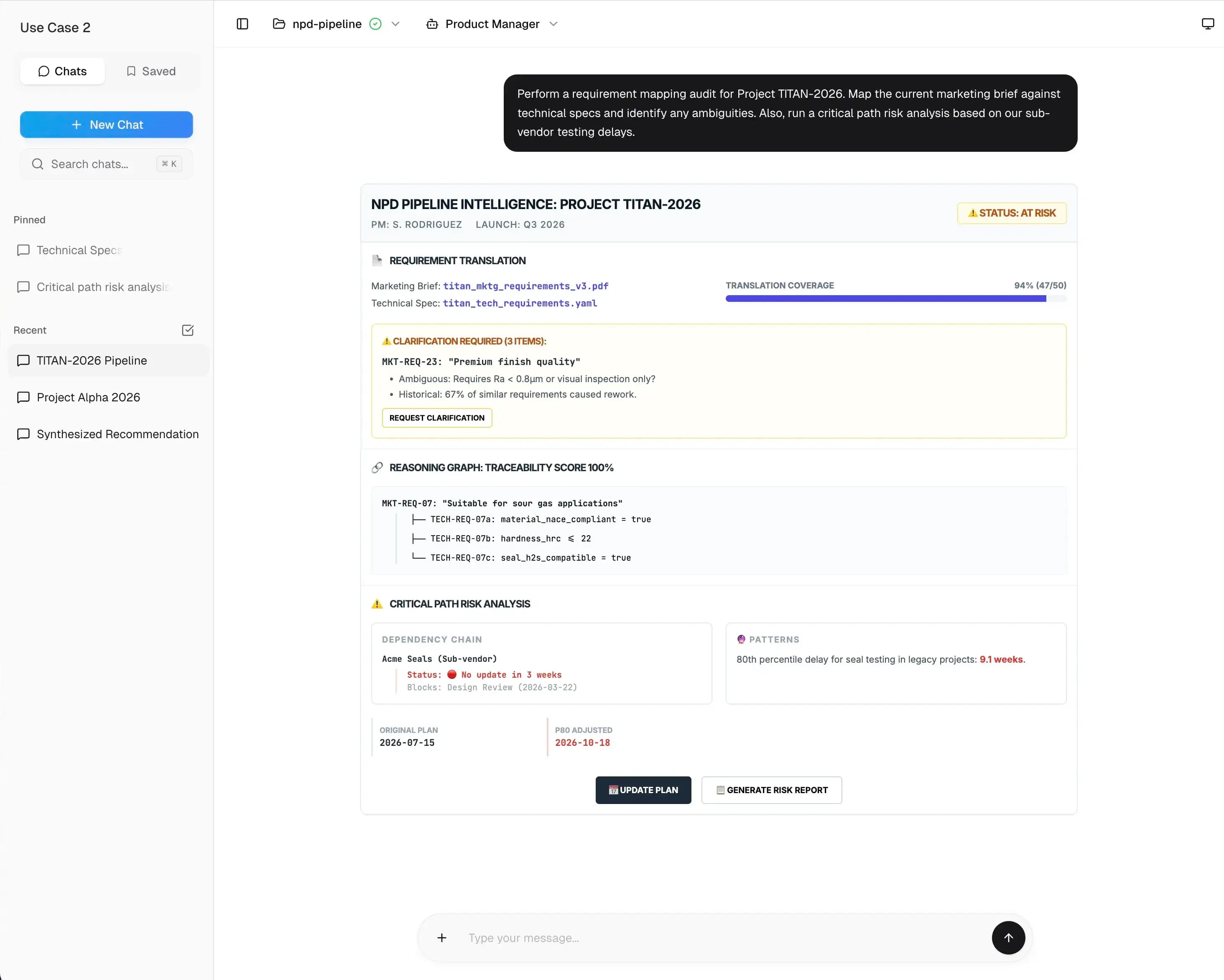

Multi-Dimensional Requirement-to-Test Pipeline

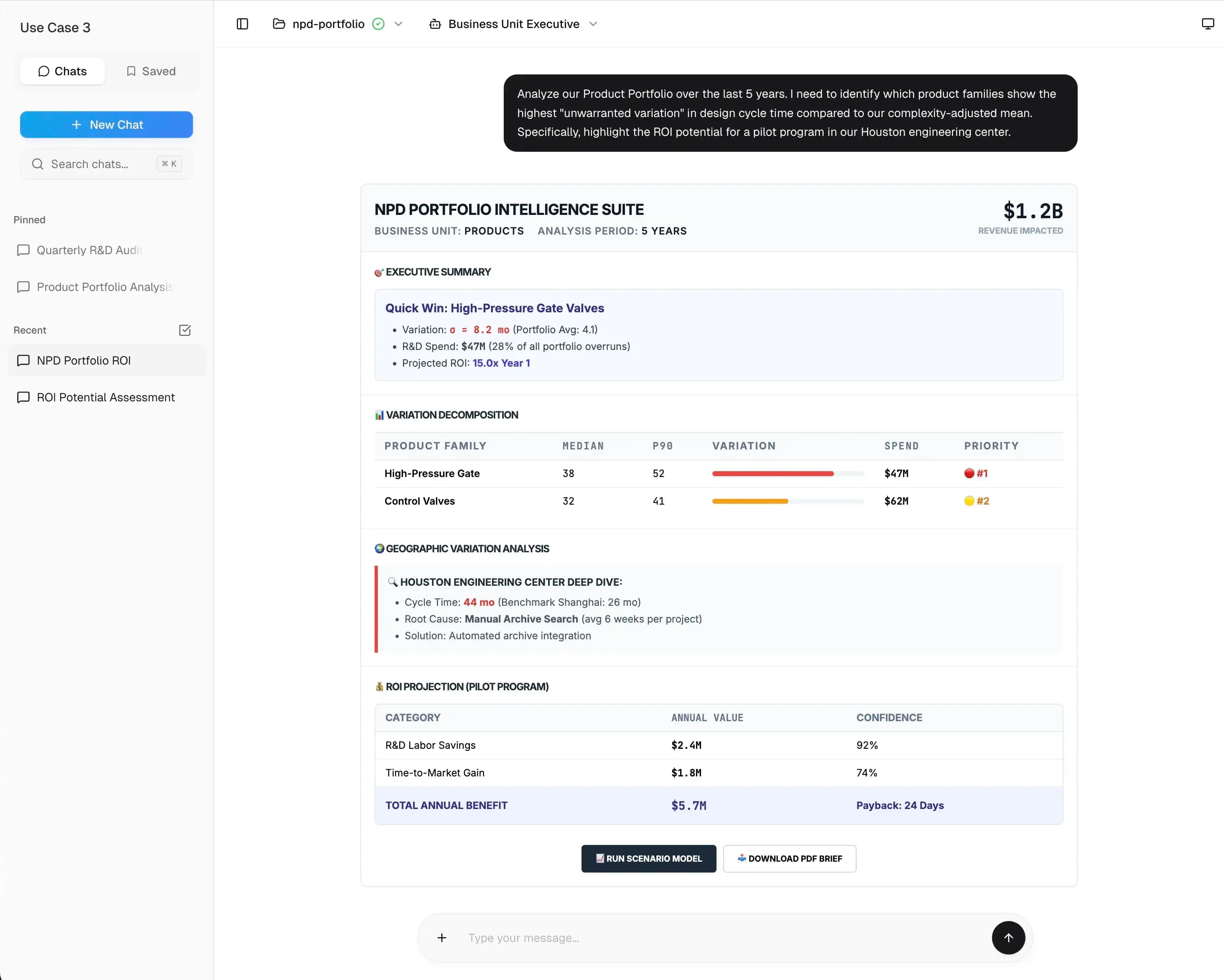

Strategic NPD Portfolio & ROI Decision Suite

The Zenera Difference: Why Industrial AI Requires Agentic Infrastructure

Capability Comparison

| Industrial Requirement | LangChain + RAG | Fine-Tuned LLM | Zenera |

|---|---|---|---|

| Engineering drawing recognition | ❌ Text only—blind to drawings | ❌ Limited vision capability | ✅ Native blueprint, P&ID, and schematic parsing |

| CAD geometry reasoning | ❌ Cannot process 3D models | ❌ Cannot process 3D models | ✅ STEP/IGES analysis and synthesis |

| Visual failure analysis | ❌ Cannot see images | ❌ Basic image description | ✅ Cross-modal fracture-to-design correlation |

| Diagram and drawing generation | ❌ Text output only | ❌ Text output only | ✅ Annotated engineering drawings output |

| 80-year legacy archive reasoning | ❌ Context overflow | ❌ Training data staleness | ✅ Hierarchical multimodal indexing |

| CAD/PDM bidirectional integration | ❌ No connectors | ❌ Not applicable | ✅ Self-coding API synthesis |

| Domain-grounded code generation | ❌ Generic code fails validation | ❌ Limited to training data | ✅ Standards-aware synthesis |

| Multi-system transactional joins | ❌ No transaction support | ❌ Not applicable | ✅ LakeFS-backed operations |

| Reasoning graphs with traceability | ❌ Text matching only | ❌ No graph capabilities | ✅ Formal requirement-to-test chains |

| Predictive analytics with confidence | ❌ No statistical modeling | ❌ Probabilistic only | ✅ Monte Carlo with historical calibration |

| Geographic variation analysis | ❌ Cannot segment by center | ❌ Not applicable | ✅ Multi-dimensional decomposition |

| Executive-ready visualizations | ❌ Text only | ❌ Text only | ✅ Interactive persistent dashboards |

| PBAC security enforcement | ❌ Application-level only | ❌ Not applicable | ✅ Corpus-level Azure Entra ID |

The Compounding Value

Each use case creates reusable organizational capability:

| Use Case | One-Time Value | Persistent Asset |

|---|---|---|

| Legacy-Informed Design | Single design validated | ValveGPT available to all engineers, learning from every query |

| Requirement-to-Test Pipeline | One project de-risked | Reasoning graph infrastructure accelerates all future NPD |

| Strategic NPD Portfolio | One pilot prioritized | Decision suite enables continuous portfolio optimization |

Conclusion: Breaking the 40-Month Barrier

The valve business unit goal—compressing 40-month design cycles to 10 months—is not achievable with incremental AI tooling. RAG can answer questions about documents. Fine-tuned models can generate plausible text. Neither can:

- See and reason over engineering drawings—blueprints, P&IDs, assembly diagrams, and GD&T annotations

- Analyze failure photographs and correlate visual patterns with design features

- Generate CAD geometry and engineering drawings—not just text descriptions

- Reason across 80 years of heterogeneous archives including visual artifacts

- Synthesize integrations with proprietary CAD and simulation systems

- Build auditable traceability chains from marketing requirements to validation tests

- Predict timeline risks using historical pattern analysis

- Decompose portfolio variation to identify highest-ROI improvement opportunities

These capabilities require engineering AI infrastructure—not text chatbots:

- Native visual recognition for blueprints, diagrams, and photographs

- CAD generation and modification capabilities for geometry synthesis

- Engineering drawing output with proper annotations and GD&T

- Transactional memory for safe multi-system operations

- Self-coding agents for arbitrary integration synthesis

- Durable workflows for long-running engineering processes

- AI-powered alignment for complex reasoning chains

- Persistent applications for reusable organizational intelligence

Zenera is not a chatbot bolted onto engineering systems. It is engineering AI infrastructure—purpose-built for the visual reasoning, CAD integration, diagram generation, and audit requirements of industrial manufacturing.

The question is not whether AI can transform industrial design cycles. The question is whether your organization will attempt transformation with text-only chatbots—or deploy engineering AI infrastructure that reasons, designs, and documents like your best engineers.

For technical architecture details, see the Zenera Capabilities Document.

For the enterprise AI adoption analysis, see From Tokens to Intelligence.